Capabilities > Injection Molding

With years of experience in the industry, ICHIPLAS specializes in producing precision plastic parts for a wide range of applications. Our state-of-the-art facility and advanced equipment allow us to offer fast turnaround times and competitive pricing, while maintaining strict quality control measures.

Our plastic parts are utilised in a myriad of industries, including consumer products, medical devices, automotive, and renewable energy sectors. With Ichiplas, you get a combination of expertise, innovation, and commitment to quality and sustainability that is unparalleled in the industry.

From concept to finished product, we are committed to providing superior service and exceptional quality to our customer.

Injection molding is widely recognized as the most cost-effective method for producing plastic parts at scale. This process involves injecting molten plastic into a mold tool and then ejecting the solidified plastic part. This cycle is then repeated hundreds or thousands of times.

- Competitive pricing

- As the same mold tool is used for each part, the cost of each unit can be driven down to just a few dollars or less.

- Consistent quality

- Using the same mold tool, supplemented by strict quality assurance processes, also ensures that the quality is consistent across every parts.

- Fast turnaround

- Our flexible operations and production lines can support fast turnaround times.

- Customisable

- Injection molding also offers the greatest range of materials, colors, surface textures, cosmetic finishes and polishes when compared to 3D printing or CNC machining.

Machines

Production capacity is across 40 units from Arburg, Toshiba, Nissei, and Sumitomo, with tonnage of 50-360 tonnes.

Materials

A wide range of materials can be used, including common ones listed below. There are also other types of plastic resins used in injection molding, each with their own unique properties and advantages. The choice of resin will depend on the specific requirements of the product being manufactured.

- 1. Polypropylene (PP)

- 2. Polyethylene (PE)

- 3. Acrylonitrile Butadiene Styrene (ABS)

- 4. Polystyrene (PS)

- 5. Polycarbonate (PC)

- 6. Polyamide (Nylon)

- 7. Polyoxymethylene (POM)

- 8. Thermoplastic Elastomers (TPE)

- 9. Polyethylene Terephthalate (PET)

- 10. Acetal (POM)

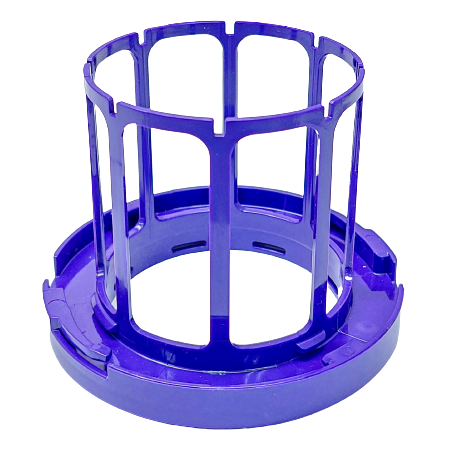

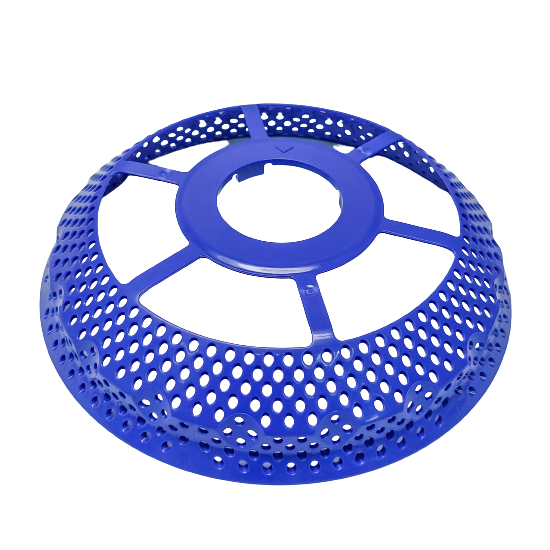

Product Gallery

Get Free Quote

Contact us today to learn more about our services and how we can help you with your next project.